|

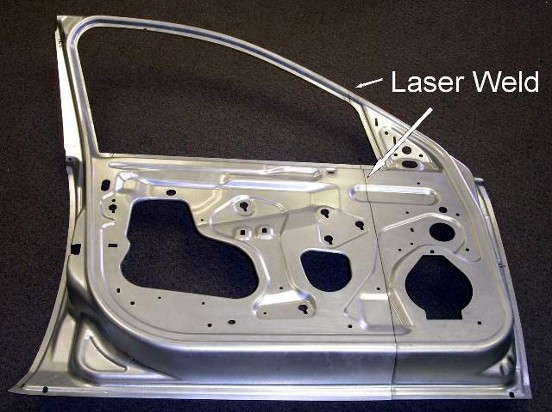

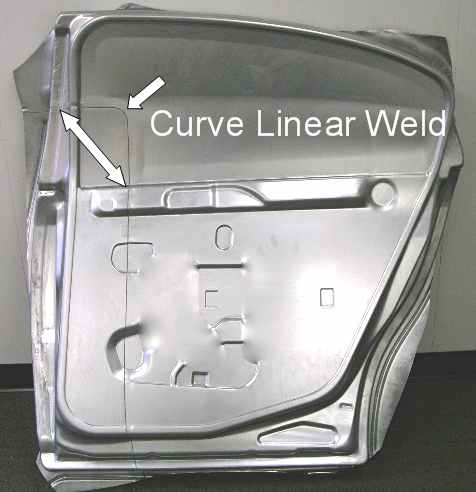

Laser-welded blanks are typically composed of different

types and thickness of steel, which are welded together

into one piece. The piece is then stamped into shape as a

single unit such as an automotive door or body side panel.

Using this method, manufacturers add strength to

parts where it is needed, reduce weight, improve

performance, better corrosion protection by the elimination

of overlapped joints, and reduce costs due to the reduction

of dies, presses, etc. due to fewer production steps.

Blanks are welded together with a linear weld

(upper right photo),

a curve-linear (left photo), or non-linear (not shown).

Our facility is spacious with ample room for inventory segregation, inspection, and process development. Our building features

a delivery bay area and a pick up bay area with sufficient materials handling equipment for

production volumes.

Weight Reduction

Weight Reduction

Cost Savings

Cost Savings

Tooling Reduction

Tooling Reduction

Increased Structural Integrity

Increased Structural Integrity

|